Stamped seamless reducers

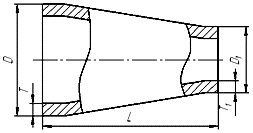

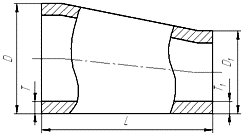

Seamless eccentric and concentric reducers are used in various pipelines including those controlled by supervisory authorities and designed to change the diameter of the a pipeline.

|

|

| Eccentric | Concentric |

Turned seamless reducers

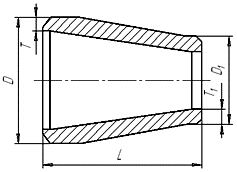

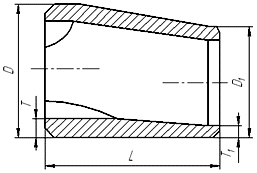

Turned reducers are made by turning a cast workpiece (forgings). The workpiece is an ordinary metal rectangle which a reducer is turned from as a result of machine treatment.

|

|

| Eccentric | Concentric |

Welded reducers

Welded reducers are used in large-diameter pipelines under low pressure. Currently they are in all pipeline types or distance-heating pipes. There are two ways of manufacturing: the first is when two ready-made reducer’s halves, pre-cut from a sheet of metal, are welded and then rolled on specialized equipment; the second is when one sheet, which is cut to the desired size, is rolled on specialized equipment, its edges are then welded. Rolling is a technological operation of a sheet deformation in a certain direction or radial deformation of a pipe. In other words, rolling is when a sheet of metal is taken and driven between two metal rollers rotating in different directions, thus obtaining the required geometry.

For orders and questions contact us: 8-800-350-0-351 (free call)