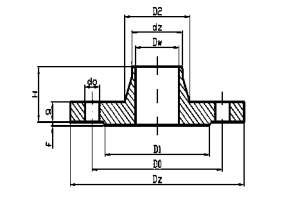

Collar flanges

There are two way of manufacturing collar flanges:

The first one is centrifugal casting when molten metal is poured into a mold and after solidification a cast workpiece is machined. Mechanical treatment goes immediately after casting;

The second way is so-called "stamping" when a cast workpiece is additionally forged using a blacksmith's hammer or press, and then machined. Forging is performed in order to remove all available air cavities inside, which are formed as a result of casting.

The casting way without further forging is cheaper because of little waste and less labor-intensity, but it is always risky that air cavities may rest inside a flange, that means the collar flanges are less reliable.

Stamping takes more time and effort and collar flanges are more expensive. Although their quality is higher because of absence of air cavities formation inside. Therefore, under high pressure, it is more reliable to use collar flanges with additional forging.

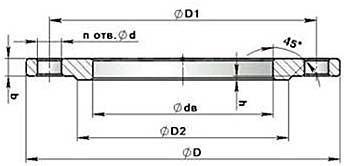

Flat welded flanges

There are two way of manufacturing flat welded flanges:

The first one is casting when molten metal is poured into a mold and after solidification a workpiece is machined.

The second is a metal sheet workpiece’s cutting (gas or plasma), i.e. a workpiece is cut of an even metal sheet and then machined.

Casting is cheaper because of little waste, but it is always risky that air cavities may rest inside, that means the flanges are less reliable

Cutting from sheet of paper leaves a lot of waste, so the flanges are more expensive, but they are of better quality because of the fact that there are no air cavities inside.

Therefore, in a pipeline under high pressure, it is more reliable to use flat flanges manufactured with cutting.

For orders and questions contact us: 8-800-350-0-351 (free call)