Our lab controls the quality of our products.

We perform spectral rapid analysis of all the pipeline parts using BELEK which allows us to define chemical composition of a semi-finished product, workpiece (blank) and finished product.

If a customer requires, the pipeline parts, which are manufactured at our enterprise, are tested on nominal mechanical properties and intercrystalline corrosion. We also carry out hydraulic tests.

The pipeline parts, which are manufactured at our enterprise, are tested on nominal mechanical properties and intercrystalline corrosion as well as we carry out hydraulic tests.

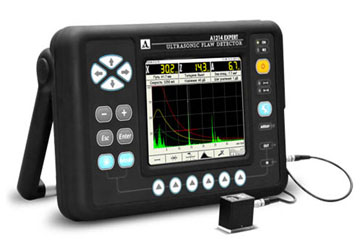

Ultrasound flaw detector A1214 EXPERT

A completely digital, small-sized and ultrasound flaw detector of common use which is able to perform typical and specialized ultrasound control and provide high productivity and accuracy of measurements.

It allows to:

- Control welded seams;

- Search for corrosion, fractures and internal layering as well as other defects;

- Define coordinates and value some defects such as material’s integrity and homogeneity disrupting in metal and plastic products;

- Measure thickness of a product;

Thickness gauge A1209

Application:

A thickness gauge allows to measure steel thickness from 0.7 to 300 mm, it helps fulfill multiple tasks in thickness measurement of a metal. It controls wall thickness of pipelines (plastic or metal), boilers, reservoirs, metal constructions, containers and other objects with surface roughness no more than Rz 160- and 10-mm curvature radius. Also, it allows to detect corrosion S=4mm2 inside a pipe with 2 mm and more wall thickness.

Breaking machine ИР 5143-200

A breaking machine ИР 5143-200 with additional devices which tests metal samples and products manufactured of metal as well as of other materials within its technical limits. With the help of the machine, we are able to carry out physical and mechanical testing on stretching, tightening, bending and flattening in standard temperature.