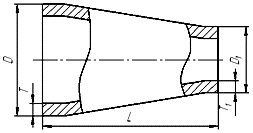

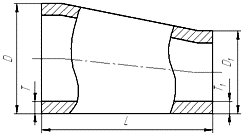

Stamped seamless reducers

Seamless eccentric and concentric reducers are used in various pipelines including those controlled by supervisory authorities and designed to change the diameter of the a pipeline.

|

|

| Eccentric | Concentric |

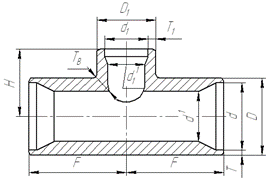

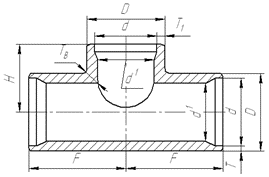

Pipeline connecting elements with three connecting edges which are designed to fasten lateral pipe branches to the main pipeline (in this way the medium changes its direction at 90 degrees angle).

Centrifugal electroslag casting (CEC) advantages:

CEC method we are able to manufacture parts from rarely used or/and chemically complex steel grades.

|

|

| Tees transition | Tees equal |

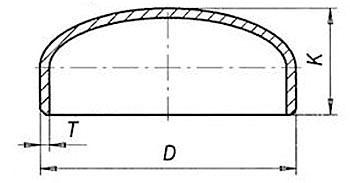

The elliptical stamped seamless caps are made with hydraulic extrusion from a sheet of metal, i.e. a part of the sheet of the desired size is cut off, then heated and using a special hydraulic press a cap is extruded from the sheet. This method of manufacturing is called stamping, so the caps are commonly called stamped. They have a small weight and dimensions and without a single weld.

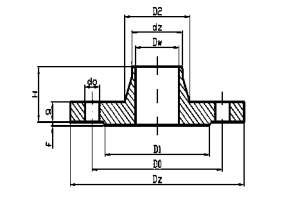

There are two way of manufacturing collar flanges:

The first one is centrifugal casting when molten metal is poured into a mold and after solidification a cast workpiece is machined. Mechanical treatment goes immediately after casting;

The second way is so-called "stamping" when a cast workpiece is additionally forged using a blacksmith's hammer or press, and then machined. Forging is performed in order to remove all available air cavities inside, which are formed as a result of casting.

The casting way without further forging is cheaper because of little waste and less labor-intensity, but it is always risky that air cavities may rest inside a flange, that means the collar flanges are less reliable.

Stamping takes more time and effort and collar flanges are more expensive. Although their quality is higher because of absence of air cavities formation inside. Therefore, under high pressure, it is more reliable to use collar flanges with additional forging.

LLC “OZZA” offers comprehensive solutions for petrochemical and gas industries, thermal power stations, hydroelectric power station and atomic power station.