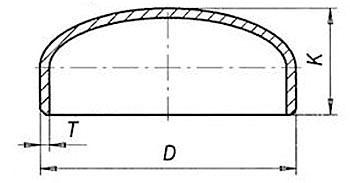

Elliptical stamped seamless caps

The elliptical stamped seamless caps are made with hydraulic extrusion from a sheet of metal, i.e. a part of the sheet of the desired size is cut off, then heated and using a special hydraulic press a cap is extruded from the sheet. This method of manufacturing is called stamping, so the caps are commonly called stamped. They have a small weight and dimensions and without a single weld.

Rotary caps

Rotary caps (obturators) are usually made by two methods: the first is casting when molten metal is poured into the mold and after solidification the workpiece is machined; the second is cutting (gas or plasma) a workpiece from a sheet of metal, it is cut from a single sheet of metal, a workpiece consists of three parts (a ring, a connecting insert and a cap), then all three parts are machined and welded. Rotary caps (obturators) made by casting are cheaper, since with such a manufacturing method there is very little waste, but there is always a risk that air cavities, which are often appear while casting, may be inside and therefore such caps are less reliable. Manufacturing by cutting from a metal sheet leaves much more waste, so the rotary caps (obturators) are more expensive, but their quality is higher since there are no air cavities.

For orders and questions contact us: 8-800-350-0-351 (free call)